Category: industrial safety

-

Winter Safety in Motion with Reflective and Non-Slip Labeling

How Can Facilities Reduce Winter Slip and Visibility Risks? Facilities can reduce winter slip and visibility risks by improving low-light visibility and increasing traction in high-risk areas. Reflective floor markings help workers and vehicles navigate safely in winter darkness, while non-slip labeling adds grip where snow melt and ice make surfaces unpredictable. The sections below…

-

Get Ahead of Facility Safety Before Year-End

A focused signage audit uncovers risks, closes gaps, and prepares your facility. As facilities wind down annual operations, it’s easy for visual communication to fade into the background. One of the simplest ways to reinforce safety before the new year is to look at the visual systems that hold…

-

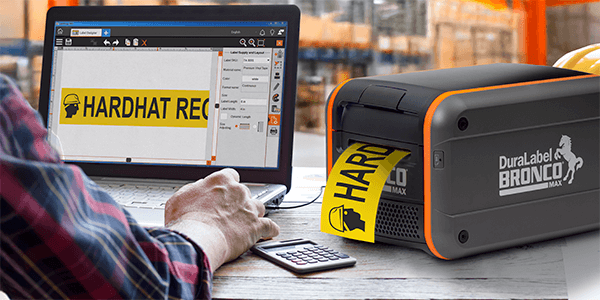

Why Now Is the Right Time to Invest in a Bronco Max Industrial Label Printer

Can Facility Maintenance Teams Afford to Skip Labeling? Facility maintenance touches every corner of a workplace, from electrical rooms and boiler areas to stairwells and storage spaces. These environments carry a wide range of risks, including energized equipment, chemical exposure, and blocked exits. When hazards aren’t clearly marked, those risks…

-

Sharp Labels, Safer Workplace

Cutting Arc Flash Hazards Before They Spark Electrical hazards remain a major source of workplace fatalities and costly downtime. In 2022, 145 workers lost their lives to electrical exposure, according to the U.S. Bureau of Labor Statistics (BLS). [1] While engineering controls and personal protective equipment (PPE) often receive the…