Most Fatal Electrical Injuries Aren’t in the Trades. Here’s What’s Missing.

Electrical injuries remain a leading cause of death in American workplaces. Despite regulatory oversight and decades of awareness campaigns, the numbers are not improving fast enough, especially for workers in non-electrical roles. The U.S. Bureau of Labor Statistics (BLS) recorded 1,940 fatal electrical injuries between 2011 and 2023. More than 74% of these fatalities occurred in non-electrical occupations, highlighting the risks faced by workers who may lack adequate electrical safety training.

Why are Non-Electrical Workers Bearing the Brunt?

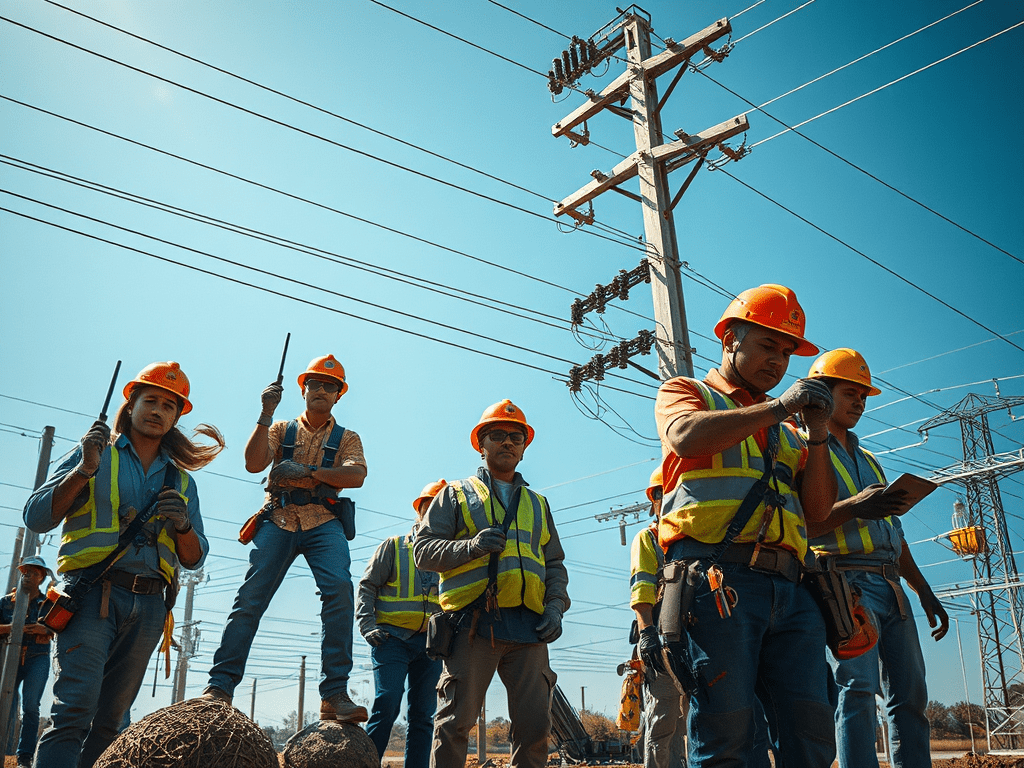

The data challenges the assumption that electrical hazards primarily threaten electricians or utility workers. According to the Electrical Safety Foundation (ESFI), construction laborers, maintenance personnel, and machine operators account for a growing share of injuries, often from indirect exposure, such as contact with overhead power lines or unexpected energization of nearby equipment.

This has implications not just for job sites, but for broader safety standards. Many employers lack structured programs to help non-electrical personnel recognize and mitigate electrical hazards. As a result, otherwise competent workers are left vulnerable to serious injuries, including burns, amputations, cardiac arrest, or death.

Where Are Electrical Hazards Most Common?

The deadliest source of injury continues to be contact with high-voltage lines. Both overhead and buried infrastructure present unique dangers. Voltage alone does not determine the severity of an injury, but factors like contact duration, grounding, and proximity to energized sources all influence outcomes.

According to ESFI, the three industries with the highest number of electrical fatalities are construction, professional and business services, and trade, transportation, and utilities.

1. Construction

This sector reported 855 electrical fatalities. Workers frequently operate near overhead power lines, use electrically powered tools, and work around unfinished systems, often without knowing whether circuits are live.

2. Professional and Business Services

Although not traditionally linked to electrical work, this sector reported 212 fatalities. Employees in roles such as building maintenance or contracted services may be exposed during routine tasks or inspections near energized components, often without appropriate training.

3. Trade, Transportation, and Utilities

With 155 reported fatalities, this broad sector includes utility workers, warehouse employees, and telecom crews. Many operate machinery near energized lines or within electrical infrastructure. Some receive safety training, but many remain unaware of the risks posed by aging equipment or exposed systems.

These numbers reflect a systemic issue. Electrical exposure is not limited to those with “electrician” in their job title. Workers across industries are routinely placed near live systems, often with little to no understanding of voltage thresholds, minimum approach distances, or personal protective equipment (PPE) requirements.

OSHA Recommendations to Reduce Risk

To reduce the risk of exposure, the Occupational Safety and Health Administration (OSHA) recommends:

- Maintaining a 10-foot clearance from overhead power lines

- De-energizing and grounding lines before working nearby

- Using non-conductive ladders

- Avoiding metal tools near energized components

- Ensuring ground-fault circuit interrupters (GFCIs) are used with temporary wiring or in wet environments.

Double-insulated tools offer an added layer of protection, especially in construction, where vibration and handling wear can degrade insulation over time.

Training Non-Electrical Workers

Under OSHA standard 1910.269, non-electrical workers may operate within restricted environments, such as substations or vaults, if they meet the definition of a “qualified person.” To qualify, they must receive training specific to the hazards, voltage levels, and protective measures relevant to their tasks.

Required knowledge includes:

- What is and isn’t safe to touch

- Maximum voltage in the work area

- Minimum approach distances

- Proper PPE and how to use it

- Safe work practices tailored to the site

Too often, employers assume these areas are safe simply because no direct electrical work is occurring. That assumption can have fatal consequences.

Labeling and Visual Communication Save Lives

Signage and labeling remain among the most cost-effective safety controls. Arc flash boundaries, buried line indicators, and voltage warnings help reduce unintentional contact and reinforce training.

Facilities should maintain up-to-date arc flash labels in accordance with NFPA 70E and ensure lockout/tagout procedures are clearly marked. Site-specific labels indicating overhead clearances or buried lines provide additional protection, especially for temporary workers or contractors.

Leave a comment